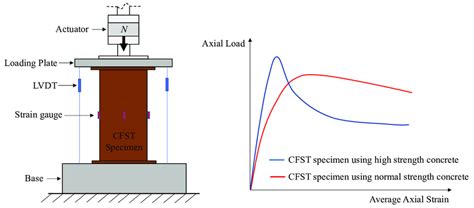

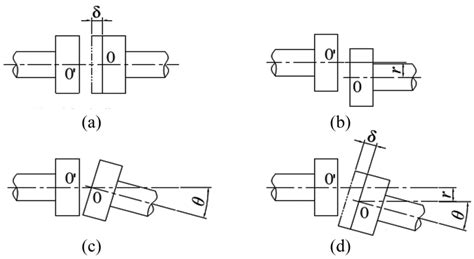

Axial Deviation Tester distribute|axial misalignment in testing : trade Using the finite element method and the deep learning technique, a mapping relationship has been established between the strain measurements on the rod specimen and the alignment deviations of the material uniaxial testing system .

WEBStatus: Ativo. Choi Jungmin é severamente intimidada no ensino médio por causa de um relacionamento ruim com Ha Joohyun quando criança. Seu único consolo é o “sonho .

{plog:ftitle_list}

Side panel MLRIT LMS Home More Log in. Home Courses; .

Alignment of the axial test machine load-train is critical to many types of mechanical testing of materials including tension, compression and fatigue [1-3]. This document describes a method . The calculated deviation values between the finite element simulation results and the test results are shown in Table 3. The average absolute deviation values of D force and D .

Shaft runout refers to the deviation of a shaft’s centerline from its true axis of rotation. It is a measure of how much the shaft wobbles or is off-center as it rotates. Runout can occur in both radial and axial directions.

Brightness Color meter fabrication

In this article, a simple and practical magnetic equivalent charge model is proposed to predict the torque of a slotted-type axial-flux magnetic coupler (SAMC) under . The loading coaxiality of uniaxial material mechanical testing (UMMT) introduces an additional bending stress, significantly affecting the admeasurement of material properties. .Using the finite element method and the deep learning technique, a mapping relationship has been established between the strain measurements on the rod specimen and the alignment deviations of the material uniaxial testing system . Dynamic interface printing is anew form of 3D printing that leverages an acoustically modulated, constrained air–liquid boundary to rapidly generate centimetre-scale .

The inflow direction significantly impacts the hydraulic efficiency of the axial-flow pump. Increased pre-swirl intensity causes more loss in the IGV passage.

axial strain alignment testing

Extreme Axis Deviation = QRS axis between -90° and 180° (AKA “Northwest Axis”) Hexaxial Reference System. Hexaxial Reference System – relationship between QRS axis and frontal leads of the ECG. How to .Suppose test scores follow a Normal distribution with standard deviation = 1 2. If 2 0 . 3 3 % of students scored below 5 0 on the test, what is the mean of the distrib There are 2 steps to solve this one.

Experimental tests were carried out for 18 sets of spring samples that differed in the number of active coils, end-coil design and spring index, and three measurements were taken per sample, at .where G k is the generation term of turbulent kinetic energy k caused by average velocity gradient, G b is the generation term of turbulent kinetic energy k caused by buoyancy, Y M is the contribution of pulsation expansion in compressible turbulent pulsation, C 1ε, C 2ε, and C 3ε are empirical constants, σ k and σ ε are the Prandtl numbers corresponding to turbulent kinetic .

During the reliability performance test, the axial thrust balancing device of GFQ150-700 was overloaded and damaged due to an unsuitable designed value of axial thrust. The designed hydraulic axial thrust with the actual value is compared in this article, and the reason for axial thrust deviation is discussed.

Related articles: Heart axis calculation, left-axis deviation, extreme axis deviation. In adults, the normal QRS axis is considered to be within −30° and 90°, right-axis deviation is considered from 90° to 180º 1.. Moderate right-axis deviation is from 90° to 120°, and marked right-axis deviation, which is often associated with left posterior fascicular block, .the axial direction (A) the horizontal direction (H), and the vertical direction (V). Horizontal measurements typically show the most vibration due to the machine being more flexible in the horizontal plane. Also, imbalance is one of the most common machinery problems and imbalance produces a radial vibration, that is, part vertical and

• The concentrated load produces a highly nonuniform stress distribution and large local stresses near the load. However, the stress smoothes out to a nearly uniform distribution • This smoothing out of the stress distribution is an illustration of Saint-Venant’s principle. He observed that near loads, high localized stresses may

Axial turbines are the most common turbine configuration for electric power generation and propulsion systems due to their versatility in terms of power capacity and range of operating conditions. Mean-line models are essential for the preliminary design of axial turbines and, despite being covered to some extent in turbomachinery textbooks, only some scientific .the prediction of the deviation angle δ is taken. The deviation angle is the difference between outflow angle and the blade metal angle at the trailing edge. It can be estimated with the well-known Carter’s deviation rule (Carter, 1950). The following is a modified version including a MVDR correction and two additional calibration . Refinement of spanwise distribution models of deviation angle and secondary loss for axial flow turbine. Author links open overlay panel H.D. Park, M.K. Chung. Show more . Modeling of three dimensional unsteady flow effects in axial flow turbine rotors. 1998, Mechanics Research Communications. MODELLING OF COMBUSTOR NON-UNIFORMITIES .

Axial dispersion and residence time distribution (RTD) have significant process implications in the design of continuous processes. Low dispersion is better for minimizing time for complete reaction and minimizing deviation boundaries. High dispersion is better for. In the test studies of transonic compressor stages, researchers discover a sudden increase in the deviation angle compared with subsonic stages, 8 and propose the following deviation models. Swan 9 considered the influences of inlet Mach number and equivalent diffusion factor, and modeled the deviation model based on linear functions. Fei and Ji 10 .

Protable Color Meter fabrication

Abstract The paper describes an improved streamline curvature approach (SLC) to the flow field analysis and performance prediction of transonic axial compressors. The previous research concerning the incidence angle, deviation angle, and total pressure loss models is discussed. Many semi-empirical correlations and curve fits were based on two . Numerical Simulation and Experiment of the Effects of Blade Angle Deviation on the Hydraulic Characteristics and Pressure Pulsation of an Axial-Flow Pump January 2021 Shock and Vibration 2021(6):1-14In the linear portion of the stress-strain diagram, the tress is proportional to strain and is given by $\sigma = E \varepsilon$ since $\sigma = P / A$ and $\varepsilon = \delta / L$, then $\dfrac{P}{A} = E \dfrac{\delta}{L}$ $\delta = \dfrac{PL}{AE} . One of the key steps in interpreting an electrocardiogram (ECG) is determining the heart's electrical axis or the sum of all depolarization vectors of the heart. The cardiac vector suggests the direction of the net flow of current through the heart.[1] Determining the electrical axis can provide insight into underlying disease states and help steer the differential diagnosis .

Unconfirmed Compressive Strength (UCS) stands for the maximum axial compressive stress that a specimen can bear under zero confining stress. Due to the fact that stress is applied along the longitudinal axis, the Unconfined Compression Test is also known as Uniaxial Compression Test. UCS is a parameter widely used in geotechnical design, but .A New Loss and Deviation Model for Axial Compressor . for several test cases shows good agreement. [DOI: 10.1115/1.4025956] . NACA65 thickness distribution and a circular-arc camber line and

axial misalignment in testing

The test compressor blade geometry is from the mid-span of a stator in a modern aero-engine compressor. . Pitchwise distribution of deviation at 0.5 chord downstream of the trailing edge. Full size image . like the axial velocity distribution, the high loss region shifts toward the suction surface for the Rough 2 blade. The mass-averaged . In the topic of “stress distribution in the tensile test specimen” only a few experimental studies have been published [3, 7–9]. The effect of wedge and screw grips on the stress distribution in a tensile test piece is clearly demonstrated in Gray and McCombe earlier work. They used round specimens and strain gauges mounted onto the test . The main contributions of the current work are (1) a FEM is proposed by taking into account the actual well trajectory and by studying the contact force distribution; (2) the overall angle change rate has a significant influence on the axial load transfer; (3) the axial load transfer is sensitive to the buckling configurations of the drill-strings.2.2. Deviation Boyer’s method [9] is used to determine the deviation angle which breaks down the deviation into indi-vidual components, according to the effects of incidence angle, meridional velocity, and 3D flow. (2.2) Cetin et al. [5] suggested a method to calculate the deviation angle at design point, modifying original

Smoothness Tester fabrication

Why perform a tensile testing? Tensile testing plays a crucial role in materials science and engineering for several reasons: Material Characterization: Tensile testing is used to characterize the mechanical properties of a material, including its yield strength, ultimate tensile strength, modulus of elasticity, and ductility.This information is crucial for understanding how a material .The Mohr-Coulomb failure criterion states that the shear strength of soil at failure (τ) is equal to:. τ = c + σ ∙ tanφ (6) Where: c is the soil’s cohesion. σ is the normal stress. φ is the angle of internal friction Hence, when more than one tests are conducted on the same material, utilizing different cell pressures, the various critical Mohr’s circles that are formed at failure . Tension test, alternatively referred to as tensile testing or uniaxial tension test, is one of the most commonly used tests to determine important material parameters such as Young’s modulus, yield strength, ultimate strength, elongation at break, Poisson’s ratio, and Lankford coefficients (R-values).

The early warning system for axial power deviation ΔΙ calculates the maximum axial power deviation ΔImax, then ΔImax would be used to calculate the maximum zone that the operational state point can reach, and it will also be used to determine whether the operational state point can return to the predetermined normal operational zone by R .

webMostrar 28+ Sites como CamWhores: . camwhores.tv. Clique aqui para ver .

Axial Deviation Tester distribute|axial misalignment in testing